Beginning of the Year to the Present Day

Description of the Boat

So called "Fantail Launch"

Length over all: 23' 3" (7,028 m)

Breadth over all: 6' 3" (1,900 m)

Draft: 1" 6.25" (0,46 m) @ 2906 lbs (1.3 tons)

The boat was designed in 1982 by Pat Spurlock (Elliott Bay Co. in Portland, Oregon). It is based on the lines of 5 Victorian Era (1870-1900) hulls, all of them with an approximate length of 23 feet. This fantail launch has been described in detail in the specialized literature. Made of cored (balsa wood) glass polyesther composite. The deck (also a sandwich construction) is already bonded to the hull. The hull is supplied with engine bearers, bow tank, floor timber, stern tube and tiller port structures already in place.

Picking-up Trip

The Elliott Bay Co., from which I ordered the boat at the beginning of February, has a selling agent in Holland (the ELOship Co. in Groningen). They had two hulls in stock and readily available. The weather however was not part of the game, testing my ability to wait patiently during a couple of weeks (I had a bad time...)

The boats are being pulled from the container

During the waiting time I ordered the equipment parts available in Groningen: 20" x 30" wheel, sterntube with shaft bearing , rudder with tiller and bearing, and the skeg.

After the weather seemed to become a bit more friendly, I arranged a picking-up date with Mr. Bäcker of ELOship for the 10th of March. And just on this day a heavy, unspected snow storm swept over the Northern part of Germany. I spent 3 hours to drive past the Hamburg area, which usually takes some 30 minutes. During the return trip I encountered icy rain conditions, so that I had to stay overnight somewhere near to Emden.

Next morning in Remels, where I stayed overnight

Weather conditions had suddenly changed overnight, driving back home was a pleasurable trip. However, the boat had to wait a couple of weeks under a plastic cover at the backyard, the weather still being unusually cold. It was not before the beginning of April that I could pull the trailer over the lawn to reach the "First and Only Steam Boat Yard of Böhnhusen", a roofed pergola attached to our house.

Underway on the garden, looking for the boat yard...

The new home for the next couple of months

A bit narrow, but the workshop is just downstairs in the basement

The boat remains sitting on the trailer during the entire finishing time. In order to allow for an easier access to the boat, and to be able to move the trailer sideways, I have removed the trailer shaft and mounted four rollers under the frame.

General Considerations

I am certainly not a fan of "plastic bathtubes", I love the traditional wooden boats. For this project however, an important argument was decisive: steam boats are often trailed over hundreds of miles, being thereby subject to an extraordinary strain because of the considerable weight of boiler and steam engine. A traditional wooden boat – irrespective of its type of construction – does not withstand such peak loads for a long time. Its structure softens and gets more and more weak with every trip. Not affected are such types of construction like cold molded and glass-covered wooden strip. I find very remarkable that the French colleagues have a preference for traditional, lapstrake boats with wineglass-type transom.

A further reason for selecting a composite hull is the considerably reduced finishing time. The Elliott Bay hull can even be used without much finishing work.

The additional equipment

Looking forward: engine bearers and floor timber

Looking backwards: Rudder bearing and sterntube support

and of course the beautiful screw (wheel)...

After deck

Fore deck

Planned Activities

All visible plastic surfaces should be covered with a wooden layer, in a similar way as carried out on the other Elliott Bay hulls of the German Steam Boat Association. It would be quite reasonable to start with the floor structure and panels. But I am not that reasonable, and would like to start with the lay-on wooden deck... ..

I am going to use mahogany for the edging planks of the deck and for the guards, as I still have some boards initially intended for canoe building. I intend to prepare myself the 50-mm-wide deck strips by resawing and planing 2" by 4" teak boards as required. I have the address of a lumber yard which sells quality Burma teak at a reasonable price (about 4000 EUR per cubic meter). Purchasing ready made deck strips is exorbitantly expensive (about 25,000 EUR per cubic meter!!).

I became valuable suggestions from different colleagues, especially concerning the type of adhesive (Sikaflex) and screws to be used for this job. Thanks to Migges (DB "Lagavulin") and to Helmut Strothjohann (DB "Vaporosa").

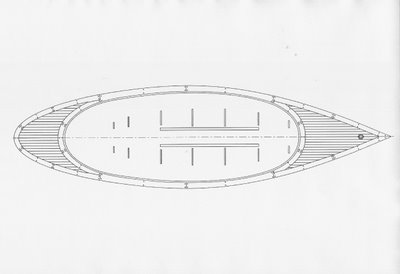

Deck layout

This is how the lay-on deck should look like. Kind of a puzzle work, but I think it looks good, and I'll certainly enjoy doing it. Due to the decks curvature, the edging planks close to the coaming and at the stern must be steam bent.

My shop in the basement is fairly well equipped for this kind of work, including powerful Elektra Beckum Machines (band saw, planing machine, milling machine with feeding unit) as well as an electrical (6 kW) steam box which I have used for canoe building work.

Well, that's all for now. I'll start updating the blogs once a month to report on the progress of my project.

3 Comments:

I would love to see your finished launch as I am considering the same hull.

I am interested in an electric propelled Elliot Bay launch.

Can you give me an update on the progress of your project?

I see that this was last put up in 2006.. any thing further? I'm building my second RC model of this boat, and I'm very thankful for the planking drawing

Post a Comment

<< Home